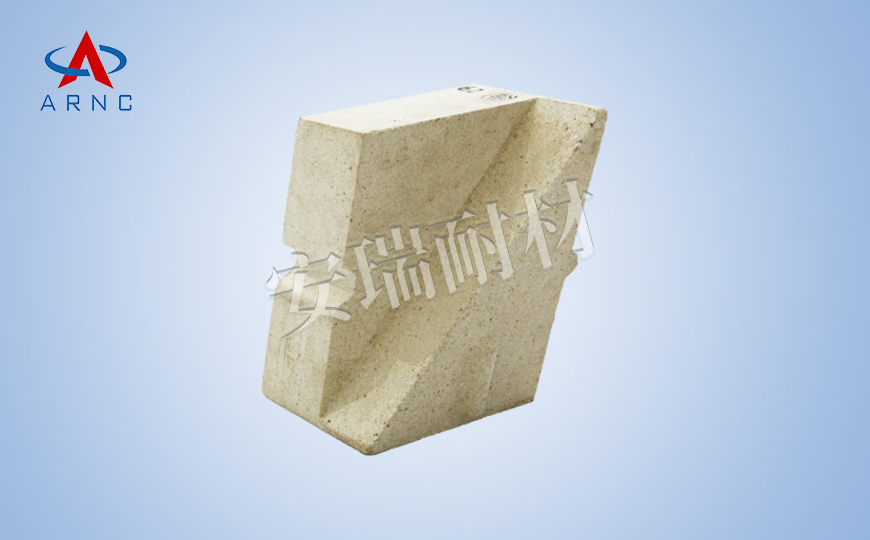

Silico brick is a fired brick composed of mullite (3Al2O3.2SiO2) and silicon carbide (SiC) as the main minerals. It is characterized by the high temperature resistance of mullite, the wear resistance and corrosion resistance of silicon carbide, and good thermal conductivity. The wear-resistant brick products are divided into: wear-resistant high-alumina bricks, silicon-moly-resistant wear-resistant bricks, reinforced wear-resistant high-alumina bricks, silicon-moly-resistant wear-resistant bricks, phosphate-based high-alumina wear-resistant bricks and other types of wear-resistant bricks.

In the technological progress of the iron and steel industry, in order to speed up the steelmaking speed, a certain amount of calcium oxide (CaO) is added to the molten iron tank in advance for so-called pretreatment. In this way, the refractory material in the tank must not only withstand the high temperature erosion of the molten iron but also resist the strong alkaline corrosion. Obviously, the high aluminum material cannot withstand it, so adding a suitable amount of silicon carbide to the high aluminum material forms a new variety. The metallurgical industry calls it a fired brick of aluminum silicate combined with silicon carbide.

After using the user's reaction, the silicon-molybdenum brick has good thermal shock stability and high-temperature strength, and is resistant to erosion, peeling, and fracture during use, and the service life is significantly extended. Silico brick is mainly used in the transition zone, calciner and cooling machine of small and medium-sized cement kilns.

Clay 19 hole brick

Mullite-cordierite brick

Mullite-cordierite brick

Anchor brick